Coffee Cherry Processing

41% Pulp and Skin

18% Slime part of bean

2% Endocarp Skin

39% Bean and seed coat

Once the ripened cherries picked from the plantations the berries processed in two ways either Dry or Wet process according to the demand.

The cherry processing is very important in order to bring out the best flavours in the coffee beans.

This approach yields an exceptionally pristine cup, characterized by subtle yet vibrant flavours and a distinct acidity. To optimize the flavour profile of the coffee beans under processing, it is crucial to swiftly separate the coffee cherries from the beans immediately after hand-picking. Commencing this stage of the processing method a day after cherry harvest can detrimentally impact the bean’s flavour, underscoring the importance of conducting this step on the same day.

The coffee bean is essentially a seed encased within the coffee cherry, and it is imperative to effectively separate the cherry fruit from the bean. For this we can use the below two methods:

- Dry method

- Wet process

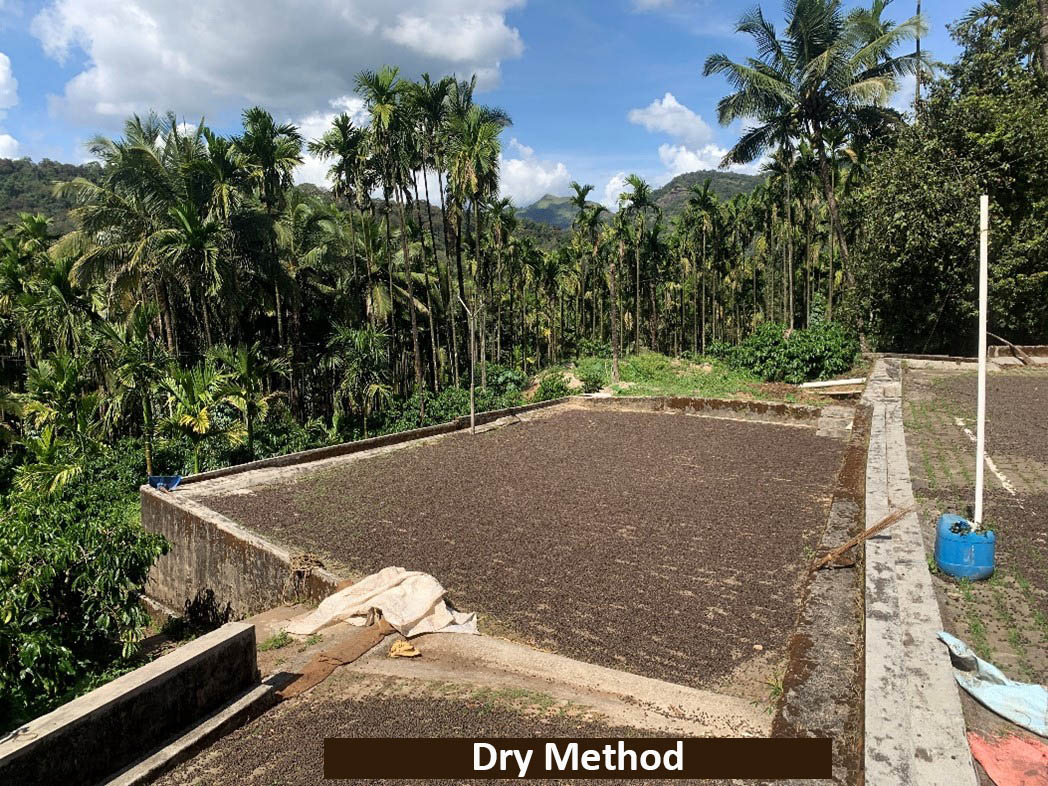

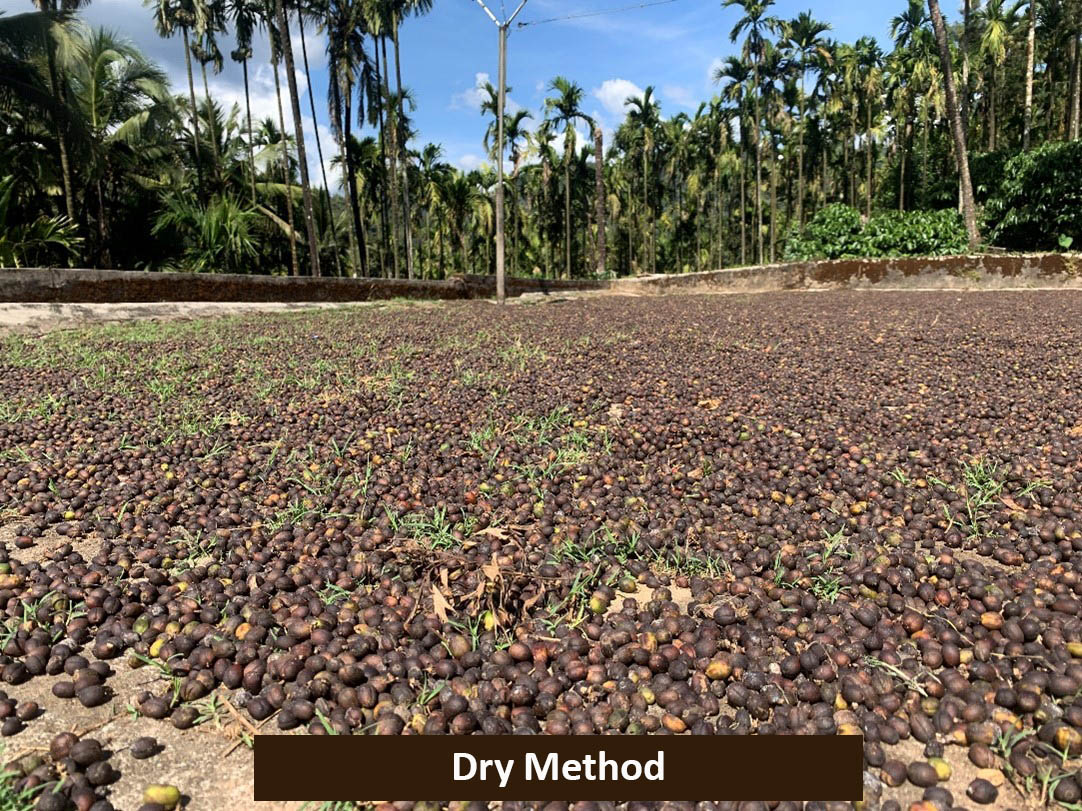

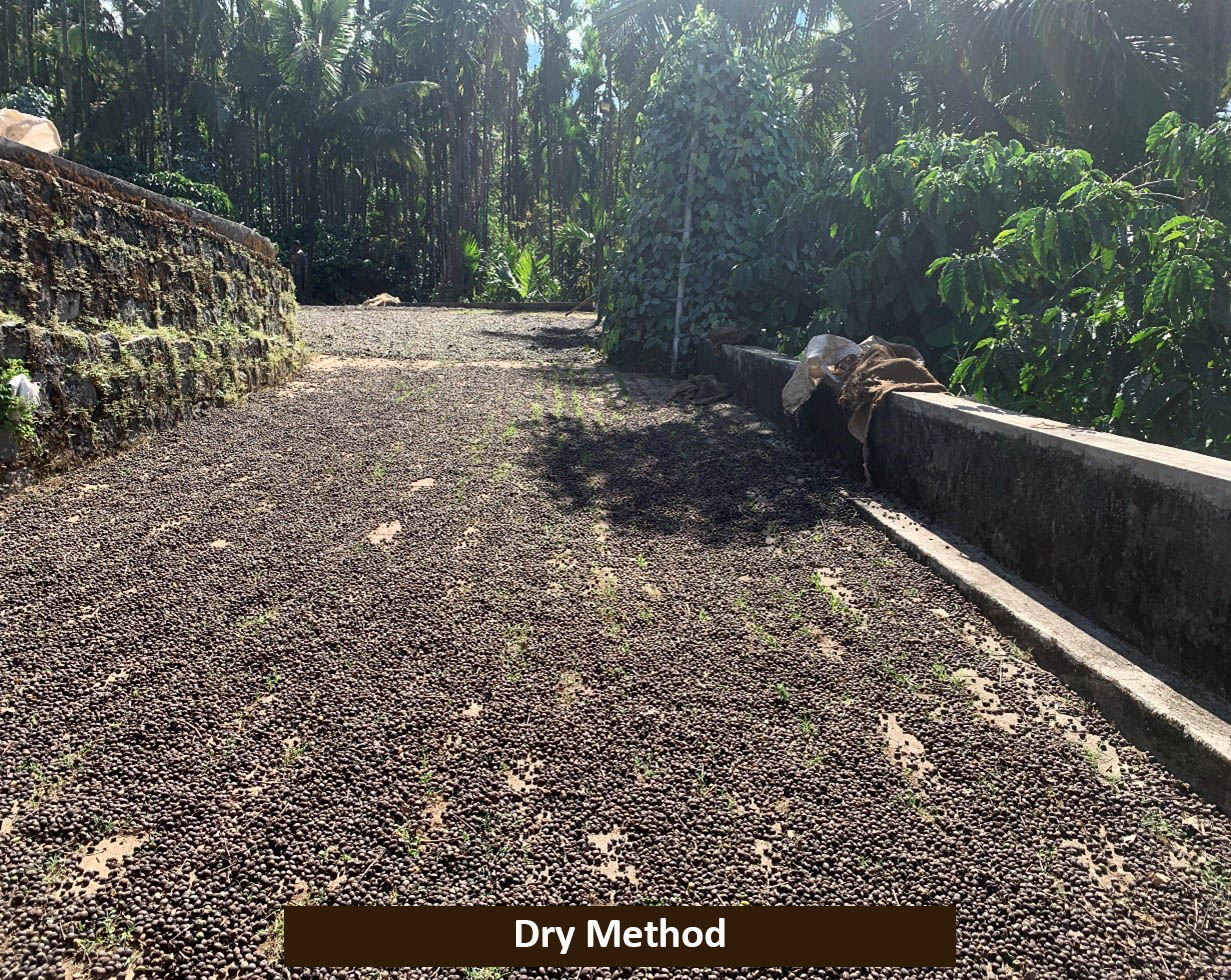

Dry Method:

Its also called Natural processing, after harvesting the coffee cherries spread-out to the cement floor to sun dry. Once dried, the cherries are mechanically de-pulped to extract the beans.

This method is recognized to imparting unique heightened sweetness and intense fruity notes. It requires careful monitoring to prevent over-fermentation or mold growth during the drying stage.

- Involves a more extended drying period, making the overall process longer.

- Uses minimal water, making it more environmentally friendly and suitable for regions with water scarcity.

Wet Process

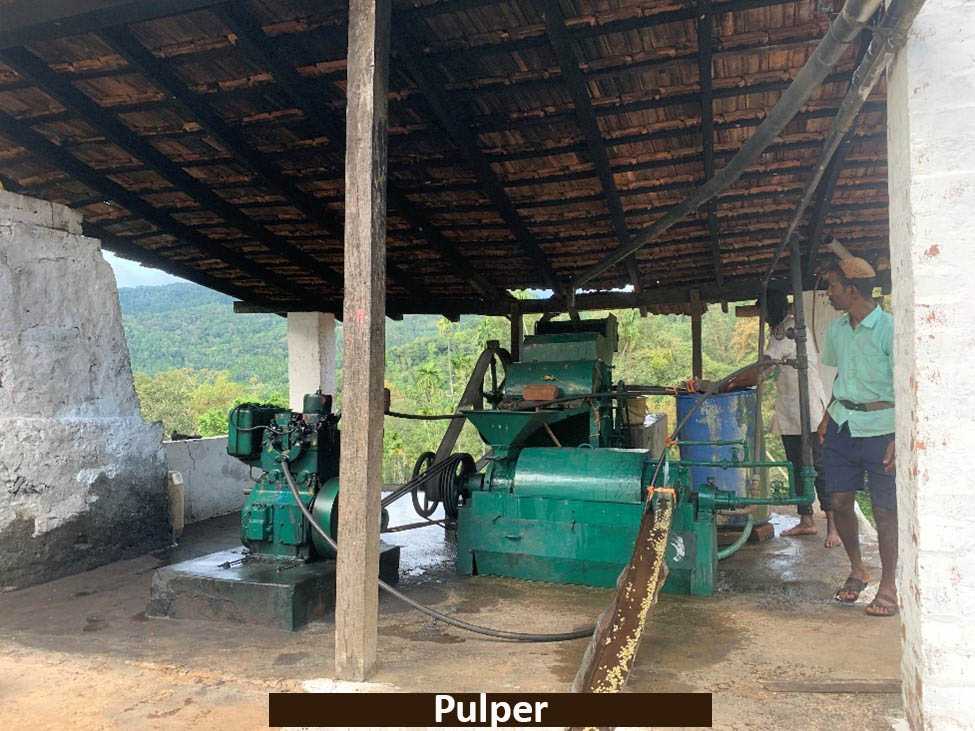

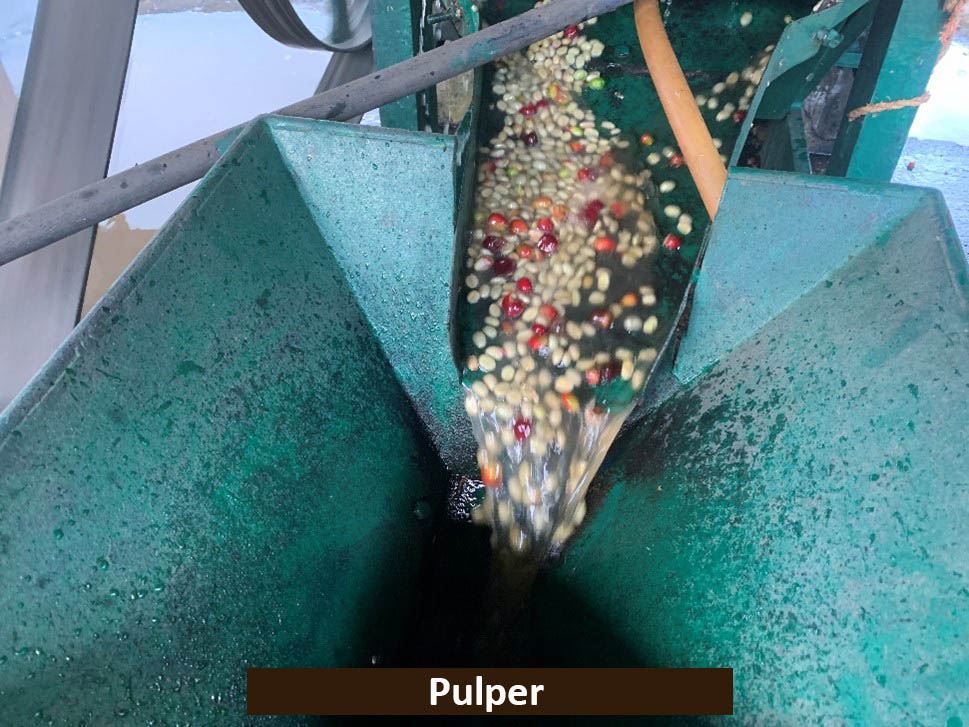

This process also known as washed processing, its characteristic with immediate removal of the outer skin and mucilage (Mesocarp) of the coffee cherry soon after harvesting. The process begins with pulping, where the cherries pass through a machine that separates the skin and pulp from the beans.

The outer skin of the seed is formed by a hard-pale light brown endocarp that becomes the “Parchment” after drying.

The process is favoured in regions with access to abundant water resources and is commonly associated with high-quality Arabica beans.

- It has a shorter processing time due to the immediate removal of the outer layers.

- Typically produces coffee with bright acidity, floral notes, and a clean taste.

- This requires sufficient of water for washing/pulping process.