Roasting: Engineering and Art

Roasting is the main process in the development of more favorable taste characteristics in coffee by input of heat source for transformation of green bean to aromatic brown bean. Before roasting the coffee, beans are in green color with beany and grassy aroma. Usually, the green coffee beans do not exhibit smell like coffee at all.

Temperature control in any heat processed product is the first step in determining ultimate quality. Coffee is unique in the food industry, in that heat dependent for development. The heat input rate of the roasting process is mainly responsible for the quality of development and flavor small change in the input of heat profile can make a dramatic change in the taste of coffee.

The roasting process is a combination of below three possibilities:

1. Direct contact via hot surfaces

2. Convection with hot roast gas

3. Radiation

- Coffee bean roasting stage

- Coffee bean Roasting stages

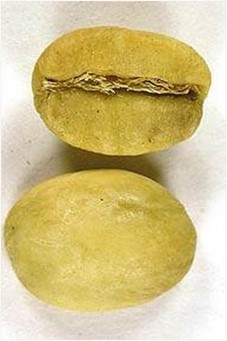

- Stage I

- Coffee bean in drying phase

- Evaporation of water vapor

- Endothermic reaction

- Green, pea like aroma

Stage II

- Coffee bean in drying phase

- Evaporation of water vapor

- Endothermic reaction

- Green, pea like aroma

Stage II

Roasting is the main process in the development of more favorable taste characteristics in coffee by input of heat source for transformation of green bean to aromatic brown bean. Before roasting the coffee, beans are in green color with beany and grassy aroma. Usually, the green coffee beans do not exhibit smell like coffee at all.

Temperature control in any heat processed product is the first step in determining ultimate quality. Coffee is unique in the food industry, in that heat dependent for development. The heat input rate of the roasting process is mainly responsible for the quality of development and flavor small change in the input of heat profile can make a dramatic change in the taste of coffee.

The roasting process is a combination of below three possibilities:

- Second crack sound

- Destruction of cell structure

- Intense cracking noise

- Bean becomes darker very faster phase

- Bitter substances are formed increasingly

- Smoky burnt flavours

- Oils are visible on the surface of beans

Bean matter will be converted into gas-mass decrease

Increase of volume

Very bitter notes, hardly typical coffee flavor

Oil migration

Increasing flameless combustion of organic materials (pyrolysis)

Non-homogeneous roasting bean cross section

Homogeneous roasting bean cross section

Short Roasting:

- Increased acidity

- Increased body

- Decreased bitterness

- Increased bulk volume

- Increased extraction yield

- Increased soluble solids

Long Roasting

- Decreased acidity

- Decreased body

- Increased bitterness

- Decreased bulk volume

- Decreased extraction yield

- Decreased soluble solids